应用

is the Natural Solution to the Man-Made Problem of Plastic Pollution!

BioLogiQ’s NuPlastiQ BioPolymer is a unique type of thermoplastic resin made with our proprietary iQ™ Technology process that converts high crystalline starch powder into a low crystalline (mostly amorphous) plastic resin.

NuPlastiQ BioPolymer, a USDA Certified BioPreferred intermediate resin, reduces fossil fuel-based plastic use and greenhouse gas emissions. They also maintain or even enhance the performance of both traditional plastics and newer biodegradable biopolymers.

NuPlastiQ has many properties that are desirable for manufacturing a variety of products, including films and bags, injection molded parts, blow-molded bottles, and thermoformed parts.

iQ™™ Based NuPlastiQ Helps Make Plastics More Planet Friendly

NuPlastiQ is made from annually renewable agricultural resources such as potatoes, corn, and cassava. For example, besides industrially manufactured starch, we use starch that remains after processing potatoes into potato chips and french fries.

must be blended with other plastic resins, including both fossil-fuel and bio-based materials.

NuPlastiQ Has Been TUV OK Certified

NuPlastiQ BioPolymer resin reduce fossil fuel-based plastic use and greenhouse gas emissions. They also maintain or even enhance the performance of both traditional plastics and newer biodegradable biopolymers.

iQ Technology-based products have many properties that are desirable for manufacturing a variety of products, including films and bags, injection molded parts, blow-molded bottles, and thermoformed parts.

The NuPlastiQ CG 1000 series has been TUV approved and certified.

BioBlends

BioLogiQ has invented a process for making homogeneous blends of NuPlastiQ BioPolymers (having low crystallinity) with other polyolefins (having high crystallinity). The resulting thermoplastic blend is called a BioBlend.

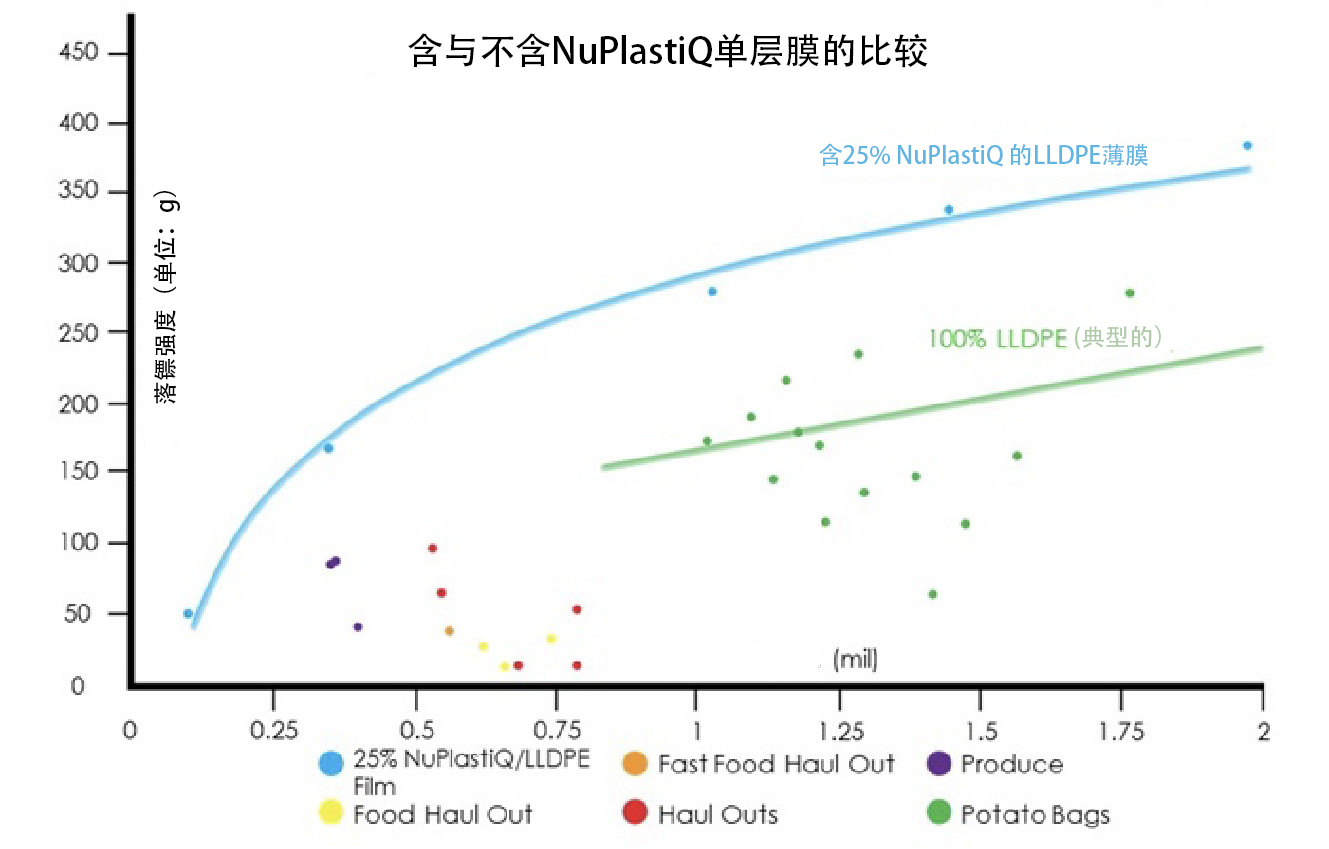

Since iQ-based products have a higher modulus (strength) than many polyolefins, BioBlends can be used to make plastic items that are stronger than those made with pure polyolefins. The chemical and mechanical bonds of plastic products made with BioBlends exhibit beneficial properties from each of the base resin feedstocks.

NuPlastiQ Family of BioBlends

使用 NuPlastiQ 生物基聚合物与传统塑料复合生产 BioBlend XP, XD和 BC 树脂, 将达到或超过传统塑料制品的性能。

高性能: 用于包装的 BioBlend XP 系列的高性能复合材料,将保持甚至增加PE、PP或PS等塑料的整体强度。它们还可以减少材料使用、能源消耗、石油基塑料的使用和温室气体 (GHG) 的产生 最多可减少50%。

- 更好的性能可以允许其薄膜的厚度降低。

- 具有非晶相结构使它很容易与PE、PP和PS复合。

- 使用 NuPlastiQ BioBlend XP 可帮助减少石油基塑料的含量和温室气体的产生,最多可减少50%。

- 使用 XP 制造的产品或包装有权使用美国农业部认证的生物基产品标签。

- 制成的薄膜具有更柔软的手感。

- 减少潜在和持久性的微塑料在海洋中积累的可能性*

耐用: 用于耐用品和硬质容器的 BioBlend XD型高耐用性树脂可改善与减少石油基塑料使用量和降低温室气体产生相关的可持续性指标,同时保持耐用性和其他强度特性。

- 保持干混树脂的物理性能、耐久性和强度。

- 通过有效添加可再生成分,减少石油基材料的使用和耗能。

- 减少潜在和持久性的微塑料在海洋中积累的可能性*

- 可以将与树脂相关的从摇篮到大门的全球变暖潜力降低高达 40%。

Compostable and Biodegradable: BioBlend BC Biodegradable and Compostable Resins for packaging and films are produced by mixing our NuPlastiQ CG (Certified Grade) resin with similar plastics such as PBAT, PLA, and PHA. BioBlends are designed to retain or enhance compostability in industrial facilities and to do so price competitively. BioBlend BC enables:

- Fossil-based material & energy reductions.

- Efficient renewable content addition.

- Reduction of greenhouse gas generation.

- Compostability of thicker parts and faster biodegradability.

Using NuPlastiQ instead of starch powder to make BioBlends makes it possible for any plastics product manufacturer to make high-quality, more sustainable, plastic products that have not been possible using starch in the past. Companies that tried to use starch or TPS in the past and were not successful can now easily use NuPlastiQ BioBlend resins on their existing equipment to make high-quality and high-performance products.

Using BioLogiQ’s process on standard compounding machines, BioBlends can be made for your application without the need for special equipment such as side feeding ports for starch powder injection.

BioBlends have been successfully made and are in use with many traditional fossil- fuel resins such as LDPE, LLDPE, HDPE, PS, PP, and PBAT, as well as with bio-based resins such as PHA, PLA, and PBS, etc. BioLogiQ continues to develop blends with various grades of the many plastic resins available in the marketplace.

Compostable Resin Blends

NuPlastiQ CG-1000 Series has been granted certification for both INDUSTRIAL and HOME composting by TUV.

Ok Compost INDUSTRIAL

Customers can use NuPlastiQ resin to produce packaging or products that meet ASTM 6400 (2012) and EN 13432 (2000). If the customer wants to certify their product and feature the OK compost INDUSTRIAL label on their packaging, they must have their product certified.

Ok Compost HOME

Customers can use NuPlastiQ to produce packaging or products can say that meets TUV’s home compostability requirements. Customers who want to feature the OK compost HOME label must have their product certified.

Fortunately, due to NuPlastiQ’s very rapid degradation rate, NuPlastiQ can enhance the overall biodegradation performance of other resins in applications where this is a desirable condition.

例如,PBAT常用作农用地膜,然而,其在农场环境中的降解速度比通常期望的要慢。 使用 NuPlastiQ / PBAT 可堆肥复合材料,降解率可设计为 30-60 天,同时保有农用地膜所需的功能性。

我们拥有将 NuPlastiQ 与各种其他可堆肥树脂(例如 PLA、PHA、PBAT、PBS 和 PCL)复合的经验。 请直接联系 BioLogiQ 讨论可堆肥树脂材料的具体需求,我们将帮助您设计适合的可堆肥复合材料。

Applications & Processes

工艺

BioLogiQ 的 NuPlastiQ 生物聚合物可用标准塑料加工设备上与其他热塑性树脂进行加工。加工工艺通常与现有工艺一致,但可能需要对工艺条件进行轻微调整,例如加工温度。

How BioLogiQ turns plants into Plastics

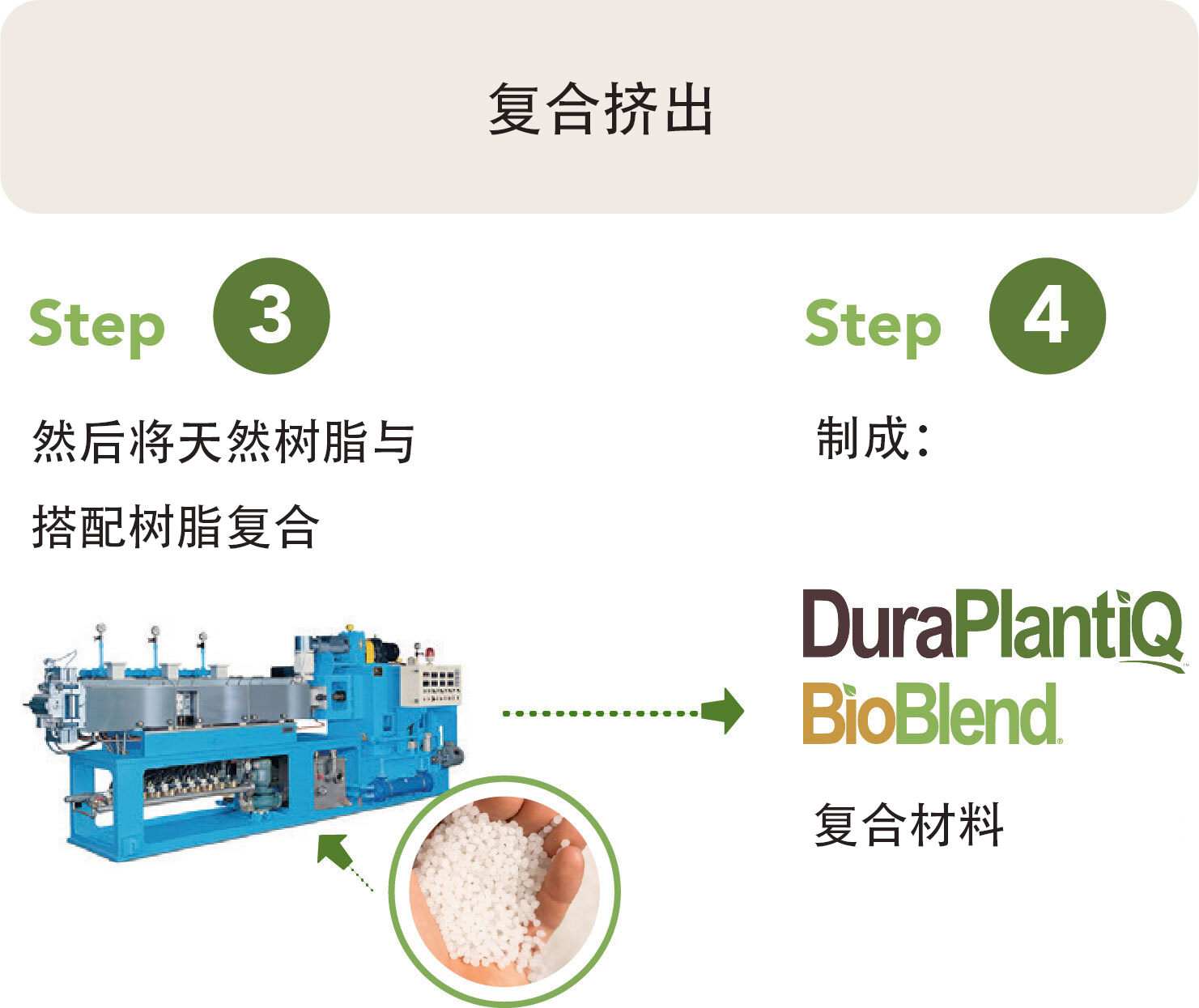

BioBlend Creation

BioBlends are made by blending BioLogiQ’s NuPlastiQ resin with other conventional resins. BioBlends normally start as Masterbatch pellets containing 50% iQ (NuPlastiQ) and 50% fossil-fuel resin which are blended on standard compounding equipment. Masterbatch BioBlends are then blended further at the final process to obtain the desired NuPlastiQ content.

Example: for typical film applications, the BioBlend Masterbatch that contains 50% NuPlastiQ and 50% virgin LLDPE resin would be fed into the blown film hopper along with an additional 50% LLDPE base resin so that the final BioBlend content in the finished film would be 25% NuPlastiQ and 75% LLDPE. Other ratios are also possible and can be easily established by the appropriate down blending configuration.

BioLogiQ can provide BioBlend compounded resins directly from our factoryies in Idaho/USA and Shaoguan/China for trial and production activities. Please contact the factory for a direct discussion of your specific needs.

吹膜

NuPlastiQ is a perfect resin for many blown film applications, including, for example, produce bags, agricultural film, and industrial packaging film.

Blown films containing NuPlastiQ can be processed on standard film blowing equipment. Films containing NuPlastiQ have been successfully made with various grades of LDPE, LLDPE, HDPE, PBAT, PLA, PHA and others. NuPlastiQ/LLDPE films as thin as 2.54 microns (0.1 mil) have been successfully blown. NuPlastiQ generally adds to the bubble stability and to the increased strength of blown films.

For best results, we like to start with a 50% NuPlastiQ BioBlend Masterbatch to make film. The masterbatch should be let down with additional resin so that the final ratio of NuPlastiQ is between 15% and 40% in a mono-layer film or in any particular layer of a multilayer film. We have developed the following Film Processing Guide for reference when performing initial product trials.

吹瓶

Blow Molded Bottles containing a NuPlastiQ BioBlend can be made for health and beauty products (such as lotion bottles). NuPlastiQ is a perfect material to enhance the sustainability of blow-molded bottles containing HDPE or PP. You can achieve a reduction in fossil-fuel content without sacrificing performance.

板材挤出和热成型

Polypropylene and Polystyrene are common materials for making thermoformed products such as cups, lids and electronic component packaging. Implementing a NuPlastiQ BioBlend solution adds sustainability to these products without sacrificing appearance or performance.

注塑

NuPlastiQ Masterbatch BioBlends can be used on standard injection molding equipment to make a wide variety of products such as cups, cutlery, custom-designed plastic parts. Implementing a NuPlastiQ BioBlend solution adds sustainability to these products without sacrificing appearance or performance.

其他工艺

In addition to these standard processes, BioLogiQ will work with you to make iQ™ Technology based products available on your proprietary processes.

BioLogiQ is happy to assist you with the optimization of processing conditions that may be necessary during your trial and production ramp-up activities. Please contact us for further information.

Standard Products

Links to documents and reports that may be useful when developing products with NuPlastiQ BioPolymers. The Technical Data Sheets and Safety Data Sheets contained are only for standard products that we sell. Please contact BioLogiQ for documents related to custom products.

Some products made with iQ™ Technology based NuPlastiQ

KWIK LOK

Kwik Lok used NuPlastiQ in its Eco-Lok bag closures. By including a natural, renewably sourced plant-based resin that requires less fuel to manufacture, NuPlastiQ helps reduce greenhouse gas emissions and overall fossil-based material use. They are completely interchangeable with our previous closures and compatible with your existing Kwik Lok machinery. Learn more at www.kwiklok.com.

BURT’S BEES

Burt’s Bees works hard to create innovative packaging solutions that are both useful and sustainable. Burt’s uses iQ based NuPlastiQ in its lip balm tubes so in the unlikely event they are not disposed of properly, the NuPlastiQ component accelerates the biodegradation process. Learn more at www.burtsbees.com.

HIGHLOCK PACKAGING

HIGHLOCK delivers the promise of providing safe, more sustainable alternatives to our customers. We make their lifestyle possible. Our child resistant Pop Top containers live by that promise, offering safety, improved sustainability and the functionality you’ve come to expect.

HIGHLOCK chose to include iQ™ in the protective packaging of their product because it provides an environmental improvement without compromise to functionality.

值得述说的故事